The application of exfin software to validate cost reductions of a novel floating wind turbine base.

Key Takeaways

Floating structure innovation that lowers the cost for Floating Offshore Wind – Floating Energy Systems’ Stinger Keel.

This is an application of exfin software to validate cost reductions of a novel floating wind turbine base. This joint industry project with foundation designer Floating Energy Systems was able to show the following:

- The Stinger Keel is expected to have both direct and indirect impacts on LCOE as compared to the Baseline.

- The direct impact is found to be 14.09% reduction on LCOE.

- The indirect impact is found to be 2.45% reduction on LCOE.

- The combined direct and indirect impacts of the Stinger Keel provide a 16.54% reduction on LCOE.

- This combined impact is estimated to be the equivalent of £556million saved over the 27-year lifetime of the project.

Project Background

This case study summaries the work Exceedence has carried out as part of the Innovate UK project ‘Stinger Keel Floating Wind Turbine Foundation UK concept development’. The project was led by Floating Energy Systems Ltd. (FESL) which is developing a novel floating structure for the Floating offshore wind (FOW) market.

Exceedence provided techno-financial modelling of the Stinger Keel within a wider FOW project, to better understand the impact on Levelised Cost of Energy (LCOE) of the Stinger Keel as compared to a baseline built using publicly available information and industry knowledge.

The financial modelling was carried out using Exceedence’s techno-financial software Exfin, that allows the user to quickly and intuitively build, analyse and optimise any offshore renewable energy project.

The Baseline project inputs used the Spar foundation type and a starting LCOE in line with an early commercial project planned and commissioned for 2025, ~£75 per MWh. By replacing the Spar foundation type with the Stinger Keel, a like-for-like comparison could be made and the impact of FELS’ floating structure on LCOE recorded.

Our Role

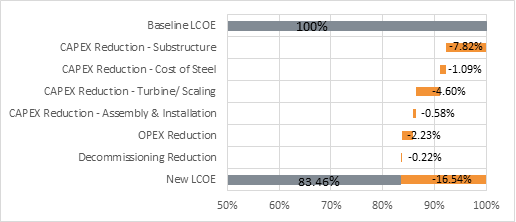

Based on the inputs from FESL regarding technology, weight, tons of steel, and manufacturing processes of the Stinger Keel, these were grouped into expected direct and indirect impacts on LCOE.

The direct impacts include: reduced sub-structure cost, fabrication and cost of steel, turbine size, turbine cost and subsequent scaling of costs, along with assembly and installation. Indirect costs were linked to OPEX costs and decommissioning.

Results

Using Exfin, the modelling established that the overall direct impact of the Stinger Keel on the Baseline projects was a 14.09% reduction on LCOE. The indirect impacts accounted for a further 2.45% LCOE reduction.

By combining the direct and indirect impacts of the LRD, the study highlights a total LCOE reduction of 16.54%.

This reduction has been estimated to be the equivalent of £556m saved over the 27-year lifetime of the project, of which direct savings due to the Stinger Keel accounts for £473m saved on CAPEX.